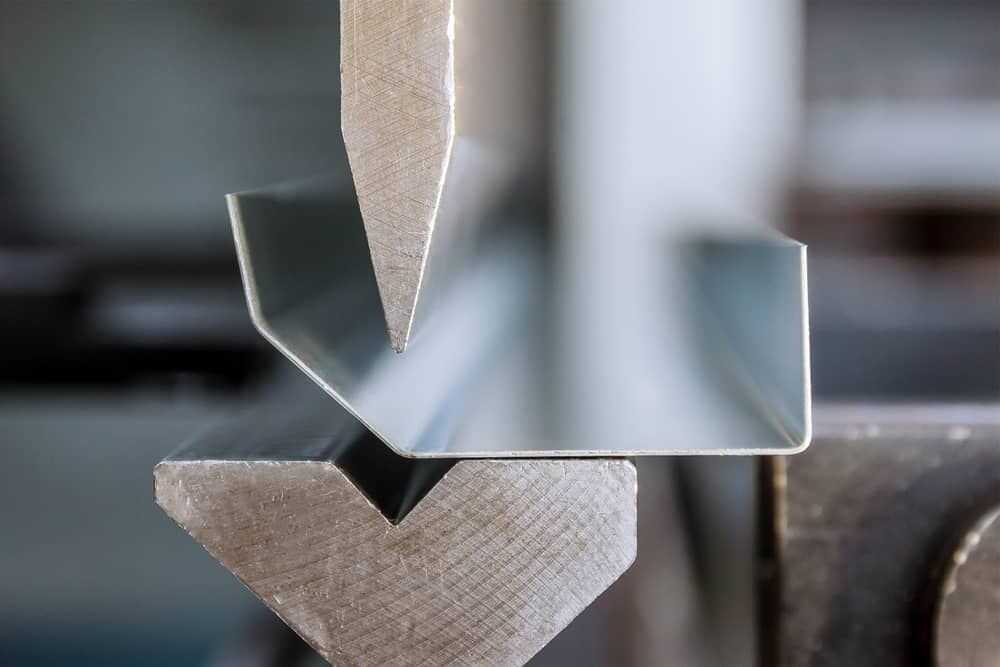

Sheet metal bending is an effective way of making products with different shapes used further as a part for different equipment. It guarantees simplicity and it is one of the essential procedures in the metal processing industry. This process involves using specialized CNC machines to bend metal sheets into specific shapes and angles, creating components that are integral to the operation of the carpentry.

Metal bending has become a more effective processing method than stamping. This method of processing is mainly used in the manufacture of a large number of products.

We performs metal bending on modern, precision machines and CNC bending centers.

To bend sheet metal and give it the desired shape, we use powerful and high-precision machines.

Sheet metal welding involves heating and melting sheet metal parts and joining them together to increase their strength or create a single integrated product. This process is widely used in various manufacturing industries, such as automotive, aerospace, construction, and equipment production. Common applications include welding metal frames, cabinets, HVAC systems, and other metal products.