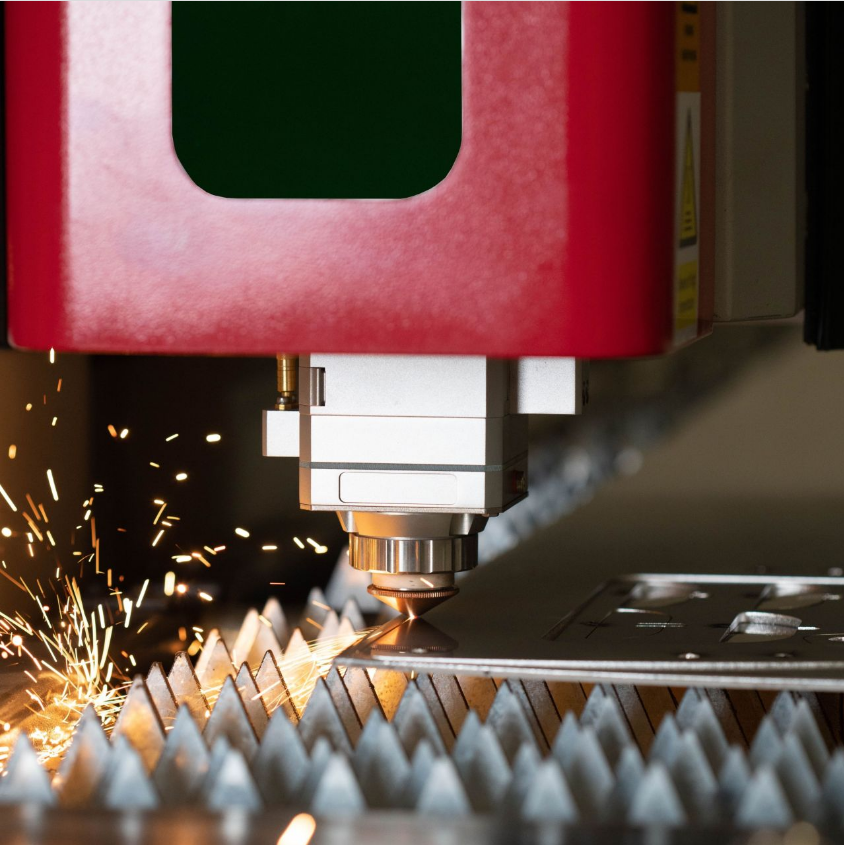

Laser cutting is a process that uses a high-powered laser to cut through different materials such as sheet metal, creating precise and clean holes. The process involves guiding the laser beam with a computer-controlled system to ensure accuracy and repeatability. Laser cutting is versatile and can be used on a variety of materials, including steel, stainless steel, aluminum, and copper.

Advantages of Laser Cutting:

High precision: Laser cutting machines can achieve highly intricate and precise results, with tolerances as tight as +/- 0.1 mm.

Versatility: Laser cutting machines can cut a wide range of materials and thicknesses. There are three 3 CNC lasers that are able to process sheet metal that is up to about 25 mm in thickness.

No tool wear: Laser cutting machines do not require physical contact with the sheet metal, so there is no tool wear or need for tool changes.

Ability to cut complex shapes: Laser cutting machines can cut complex shapes and contours with ease.

Compared to most other cutting methods, except for abrasive fluid jet, laser cutting offers a notable benefit of minimal kerf.

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes. And it's can be used in many different industries such as automobile and truck (lorry) bodies, major appliances, aeroplane fuselages and wings, tinplate for tin cans, etc.

Our factory show: